Reising Gun

The Reising gun was designed and developed by noted gun inventor Eugene Reising. It was patented in 1940 and manufactured by the old gun-making firm of Harrington and Richardson of Worcester, Massachusetts. It is said that it was made on existing machine tools, some dating back to the Civil War, and of ordinary steel rather than ordnance steel. With new machine tools and ordnance steel scarce and needed for more demanding weapons, the Reising met an immediate requirement for many sub-machine guns at a time when production of Thompson M1928 and M1 sub-machine guns hadn't caught up with demand and the stamped-out M3 "grease gun" had not yet been invented. It was a wartime expedient.

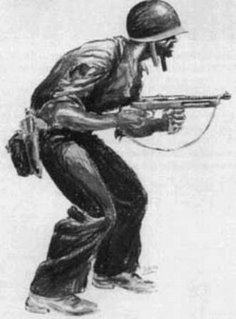

The Reising was made in two different models, the 50 and the 55. The Model 50 had a full wooden stock and a Cutts compensator attached to the muzzle. The compensator, a device which reduced the upward muzzle climb from recoil, was invented by Richard M. Cutts, Sr., and his son, Richard M. Cutts, Jr., both of whom became Marine brigadier generals. The other version was dubbed the Model 55. It had a folding metal-wire shoulder stock which swivelled on the wooded pistol grip. It also had a shorter barrel and no compensator. It was intended for use by parachutists, tank crews, and others needing a compact weapon. Both versions of the Reising fired .45-caliber ammunition, the same cartridge as the Colt automatic pistol and the Thompson.

In all, there were approximately 100,000 Reising sub-machine guns produced between 1940 and 1942. Small numbers of the weapons were acquired by both Great Britain and the Soviet Union. However, most were used by the U.S. Marine Corps in the Solomon Islands campaign. The Model 55 was issued to both Marine parachute battalions and Marine raiders, seeing service first on Guadalcanal. After its dubious debut in combat it was withdrawn from frontline service in 1943 due to several flaws in design and manufacture.

The Reising's major shortcoming was its propensity for jamming. This was due to both a design problem in the magazine lips and the fact that magazines were made of a soft sheet steel. The weapons' safety mechanism didn't always work and if the butt was slammed down on the deck, the hammer would set back against the mainspring and then fly forward, firing a chambered cartridge. The design allowed the entry of dirt into the mechanism and close tolerances caused it to jam. Finally, the steel used allowed excessive rust to form in the tropical humidity of the Solomons. Nevertheless, at six pounds, the Reising was handier than the 10-pound Thompson, more accurate, pleasanter to shoot, and reliable under other than combat conditions, but one always had to keep the muzzle pointed in a safe direction. The Model 50 was also issued to Marines for guard duty at posts and stations in the United States.—John G. Griffiths

No comments:

Post a Comment